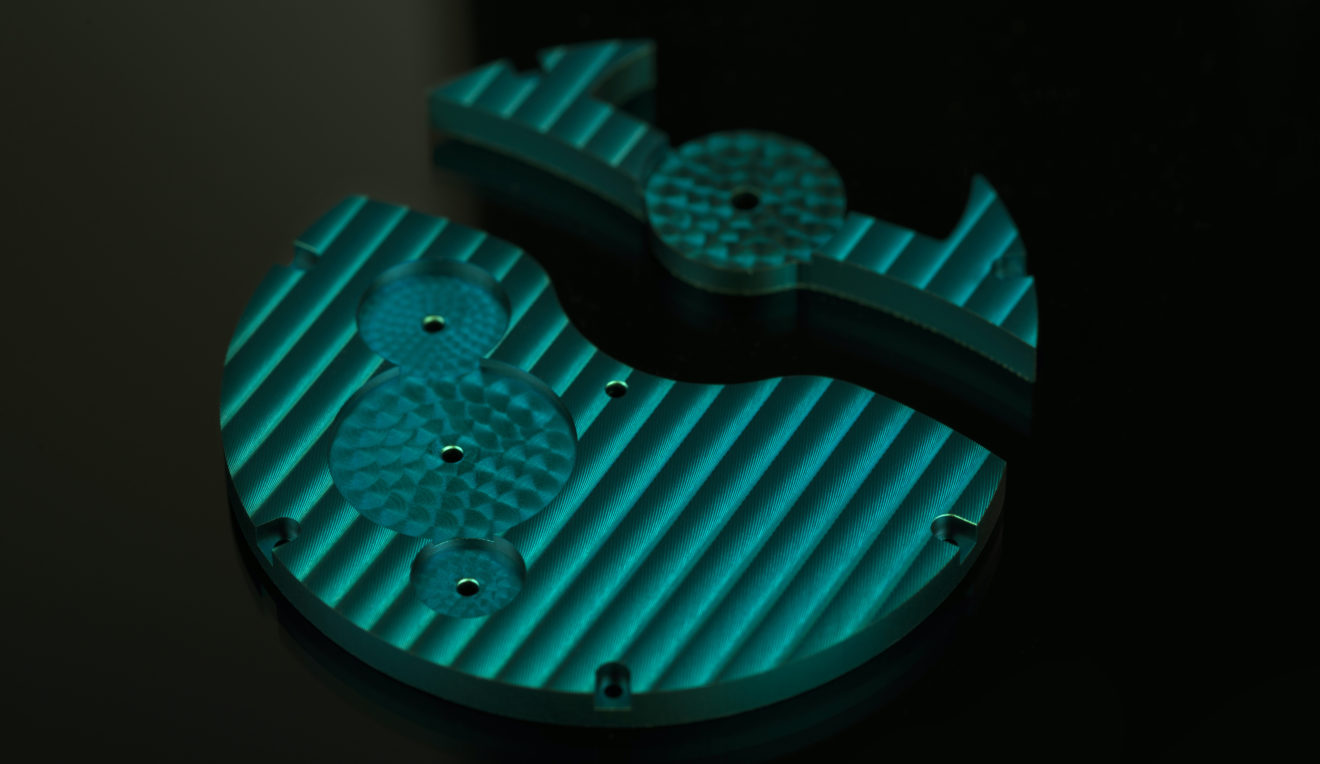

Founded in 2004, Positive Coating distinguishes itself through the development of innovative coating solutions based on PVD (Physical Vapor Deposition) and ALD (Atomic Layer Deposition) technologies, advanced physical and chemical treatments.

A @TRP, Public Relations Cabinet’s selection

Insta | Linkedin | Facebook | Insta JSH | Insta SWP | S’abonner à JSH

Located at the heart of a prestigious microtechnology industry, the company contributes to the development of excellent technological products.

Despite being unknown to the general public, watchmaking subcontractors play an essential role in the watchmaking sector. Watch brands and manufacturers have decided to shed light on these behind-the-scenes professions in recent years. As local production has gained its nobility and the Swiss Made label has become a true added value, it is fashionable to unveil this hidden world of subcontracting and highlight the richness of these collaborations, which are a source of permanent innovation.

From shadow to light

Today, no one is fooled: watch brands and even manufacturers carry out certain production operations externally, and their talent lies in their ability to surround themselves with the best companies for the development of their products. Watchmaking suppliers are thus coming out of the shadows and revealing their expertise and know-how. The consumer’s desire for transparency and traceability has convinced watch brands to share and highlight their partners.

Often developed over several generations, the expertise of Swiss SMEs gives a specific face to today’s watchmaking industry. With nearly 20 years of existence, Positive Coating is one of these companies that the watchmaking industry is proud of. The company adds color to watch designs: “Positive Coating colors time.” It is a company with independence at its core, possessing specialized know-how that has combined technologies, expertise, and talent to become an essential and unique company, resolutely focused on innovation.

A positive and proactive attitude

With one of the most active research and development departments in the industry, Positive Coating adopts a proactive approach to propose, anticipate, and prepare for the implementation of tomorrow’s surface coatings. The company analyzes color and functional treatment trends through a rich and in-depth multi-sectoral approach to offer cutting-edge coatings.

This anticipation is essential for maintaining or gaining market share. Thus, Positive Coating becomes a true force for proposal to its clients. This allows the company to open up paths of diversification that go beyond just watchmaking and luxury and access areas such as Medtech through, in particular, functional coating solutions (encapsulation, coding, conduction).

From subconstracting to cotraitance

Today, independent subcontractors like POSITIVE COATING are more reactive, more creative, and more innovative, and they are recognized and respected partners. Their professions are evolving, and so are their ways of organizing themselves. Brands or component suppliers who used to advocate for the integration of certain know-how at any cost now realize that they were dispersing themselves in professions they knew little about instead of focusing on their areas of expertise.

Having developed a unique know-how, Positive Coating can now offer solutions to its clients that they could not easily possess internally. The company anticipates product improvement and development. Positive Coating’s close collaboration with its clients also allows, in some cases, cost-sharing for research and development to go further, faster.

As such, the evolution from the notion of subcontracting to “cocontracting” makes perfect sense for Positive Coating, which aims to offer its clients creative and innovative solutions perfectly adapted to their needs through close collaboration in the early stages of projects. Additionally, while Positive Coating is an industrial producer of coatings, the company can also customize and precisely respond to its clients’ demands

.