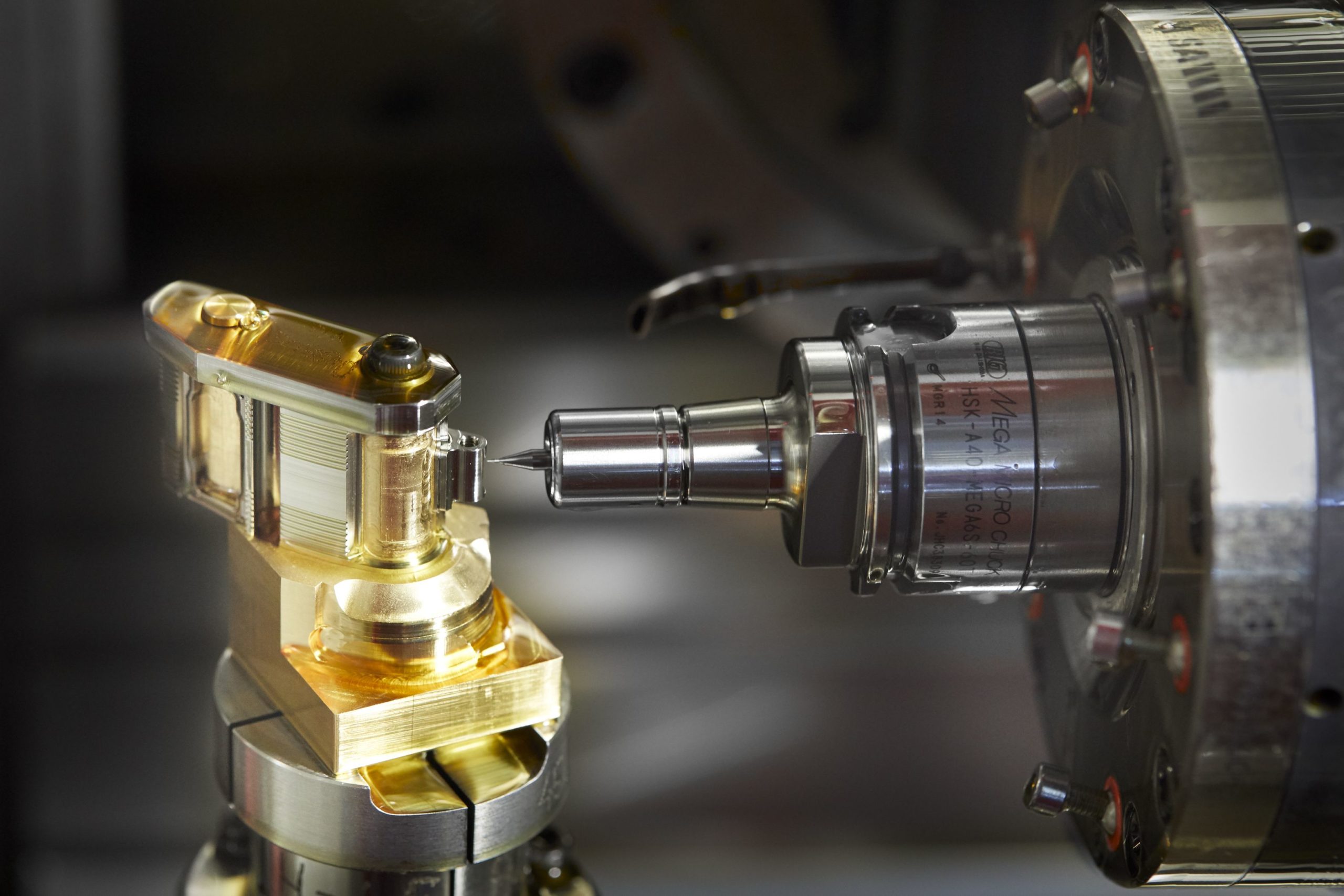

Upstairs, there is the showroom for the high-end automotive brand Lamborghini. On the lower first floor, the Swiss subsidiary of the Niru Group is machining components for the jewelry and watchmaking industries. This is Starrag’s Bumotec s191V manufacturing center.

By Henri-Maxime Khedoud, Journalist

Insta SWP | Insta JSH® | Facebook | Twitter | Linkedin

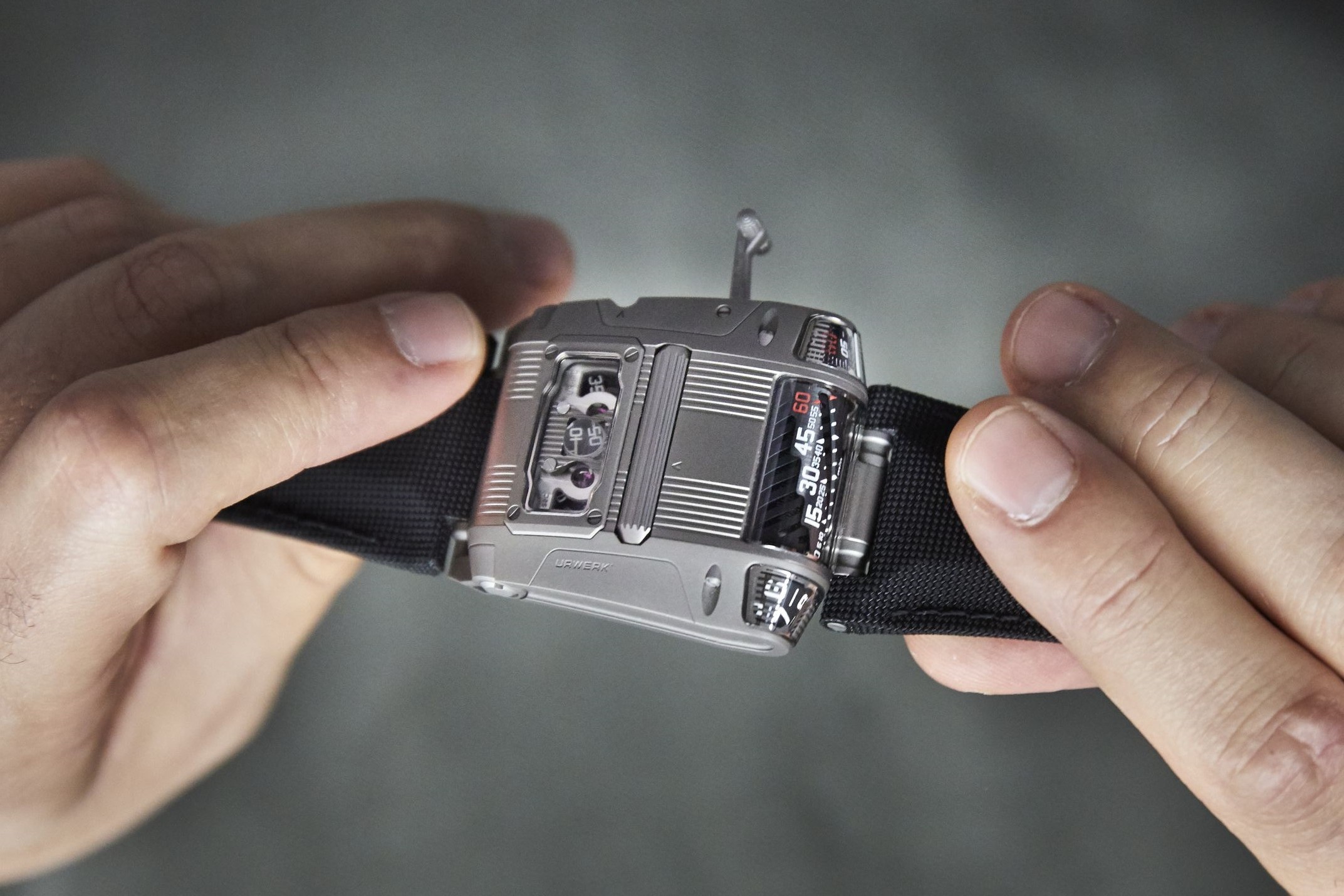

Link between the achieved watch and the machine

This workshop performs in the luxury sector, in particular because of its technology for production, one of the best of its kind. This is among other things where was made the complex case of the UR-111C wristwatch, a horological UFO signed by Felix Baumgartner, co-founder of the Urwerk watch brand. A watch case that has contributed to the buzz surrounding the mechanical model with retro-futuristic looks, because of its height of only 15 mm for 46 mm wide and without a screw-in caseback. The back is actually cut in one piece from a piece of raw aluminum and includes a 20mm deep side chamber to house the caliber. All of this was made possible by this Starrag’s five-axis Bumotec with infinite potential.

Julien Ducommun, managing director of Niru Swiss SA, says he is fully satisfied: this high-performance Bumotec s191V vertical CNC machining center is able to precisely and quicklý machine extremely complex components. His team operates a total of four CNC machine tools. The combination of linear motors, direct drives, nano-interpolation, and a high-resolution measuring capability of 1/100 μm provides excellent contouring accuracy.

Possible perspectives

Its thermostability allows components to be turned and cut continuously from early morning to late evening, without loss of precision. Thanks to this technology, the team can work simultaneously on five axes and process complete components in a single production cycle. “We now have new markets to conquer,” says Julien Ducommun, “because our company not only machines metals, but also plastics such as PEEK fiber.” A real source of supply.