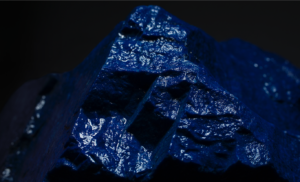

In handheld mode, the Gelsight is a surface scanner for capturing surface shapes. Already used by the MIT, American scientific police forces and high-tech industries such as ballistic engineering, Gelsight’s 3D renderings are now tackling the watchmaking industry.

Joël A. Grandjean, JSH® Magazine & Swiss Watch Passport’s Editor in Chief & Publisher

Insta SWP | Insta JSH® | Facebook | Twitter | Linkedin

Fabriques Echo published in the Journal suisse d’horlogerie JSH, June 2022

This particularly practical and transportable suitcase will energize all creatives in watchmaking and jewelry.

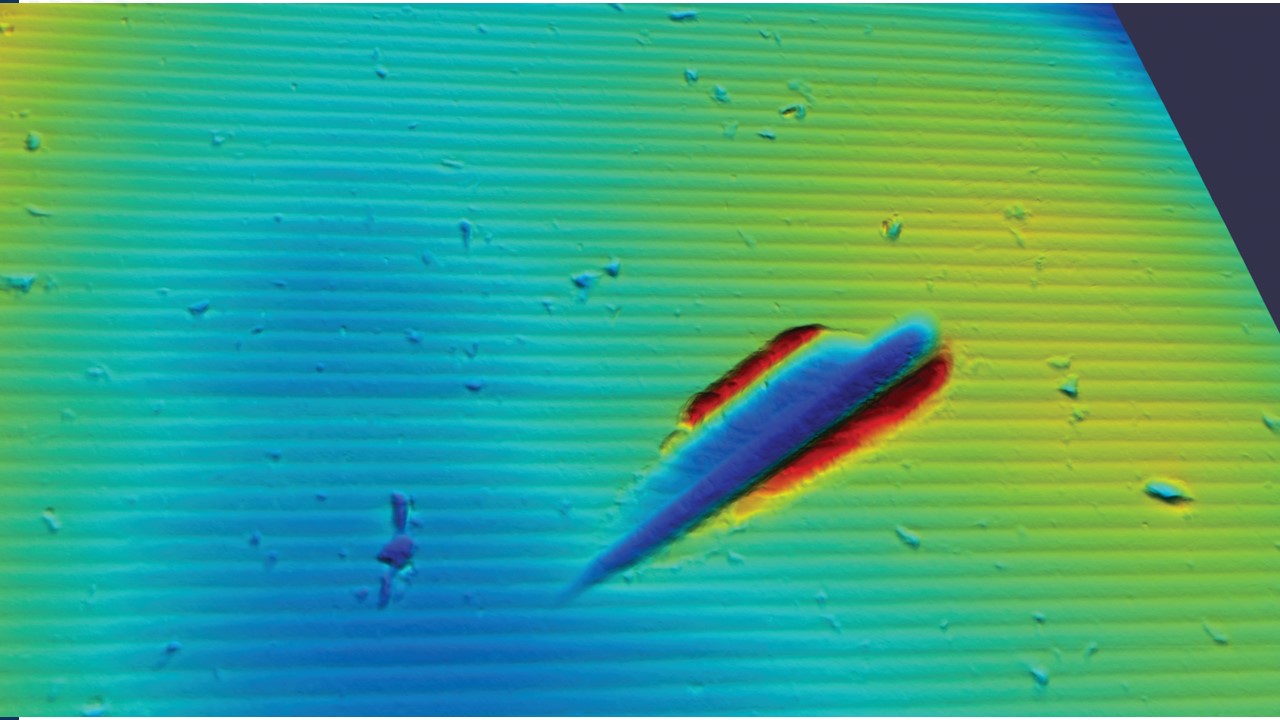

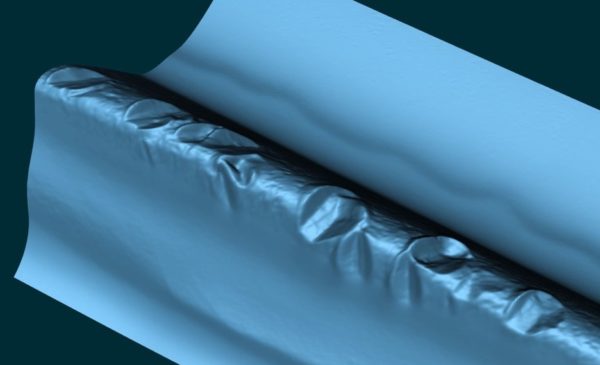

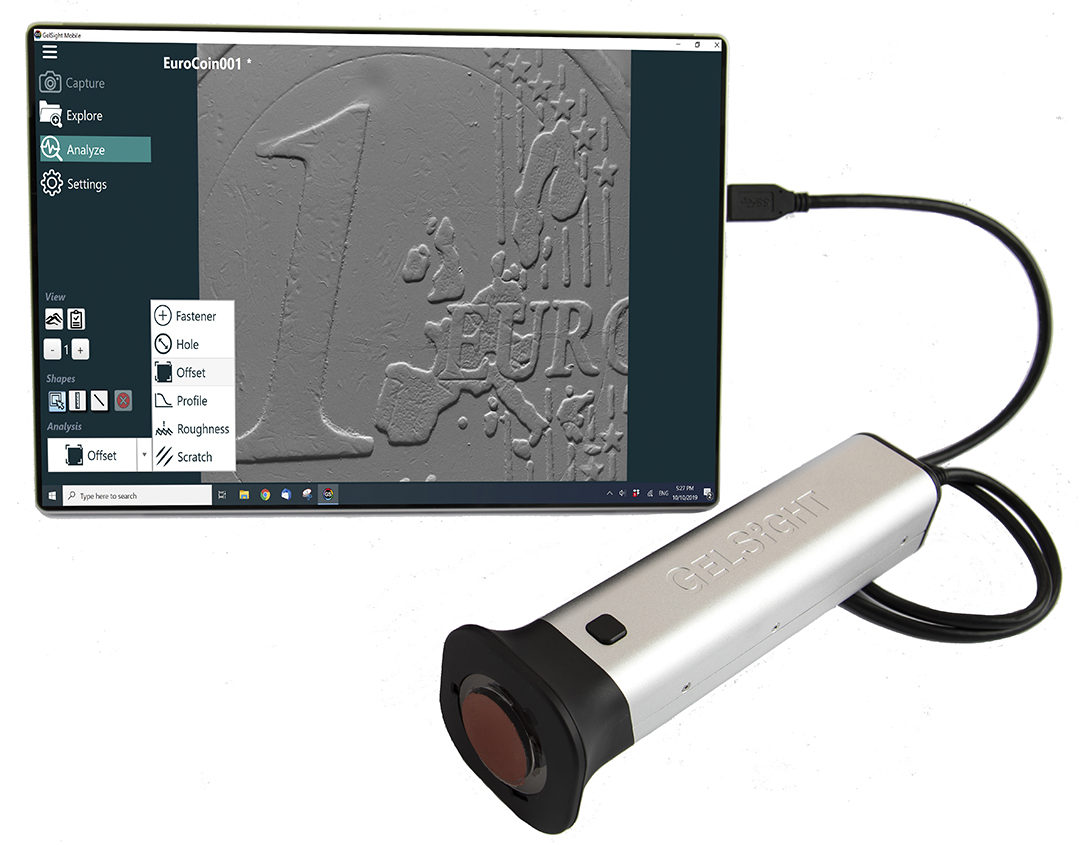

A membrane linked to the computer

Above all, this essential piece of equipment already used in the aeronautics industry helps to save precious decision-making time. Easily used to position the membrane on any surface, the gel transmits all the information required for modeling to the screen, and therefore to the computer connected to it. For example, on the back of a timepiece, a relief, a coat of arms, an engraving….

It’s so accurate that even a fabric texture can be measured, or even a fingerprint! It can therefore be used to validate the surface quality of 3D-printed objects, or even to assess the porosity and density of grains, and finally, to obtain a pre-engraved sketch before the human touch can apply its skill.

For use at Altair Consulting or at home

So, two options. The first is to visit Emeric Lignier and Paul-Henri Tinguely of Altair-Consulting, and after a few dozen minutes, to obtain an acquisition to produce an output from an in-house 3D printer. In a flash, a set can be modeled and translated into STL language. The other solution is to acquire this technology, so as to have it ready at hand. The Plan-Les-Ouates-based company is the only distributor of this kit in Switzerland.